TITANIUM AS A BIOMEDICAL MATERIAL FOR IMPLANTS

TITANIUM AS A BIOMEDICAL MATERIAL FOR IMPLANTS

Abstract

Titanium are alloy are considered as the most

promising and the most attractive material in the biomedical application. As

titanium has been very long favored for the biomedical application.

However, for permanent implant applications the alloy has a possible toxic

effect resulting from released vanadium and aluminium. For this reason,

vanadium- and aluminium free alloys have been introduced for implant

applications.

Introduction

As material used in the

wide range of the application and must be exhibit and the properties. The main

important of the used in the part of materials used for fabricating implants is

biocompatibility, followed by corrosion resistance. The main metallic

biomaterials are stainless steels, cobalt alloy, and titanium and titanium

alloys. Stainless steel was the first metallic biomaterial used successfully as

an implant. In 1932, the cobalt-based alloy named Vitallium was developed for

medical applications. Titanium is the newest metallic biomaterial. In both

medical and dental fields, titanium and its alloys have demonstrated success as

biomedical devices

The titanium is used in

the biomedical industry due to the excellent mechanical properties and the good

biocompatibility as the titanium as some of the steel, its density is only half

as the steel. The titanium is uses broadly use in the number of field,

including aerospace, power generation,

automotive, dental and medical industries. The first metal alloy developed

specifically for human use was the “vanadium steel” but it was no longer used

in implants because its corrosion resistance is inadequate in vivo. Later in

the 1950s, 18-8sMo with very low carbon content (known as 316L) stainless steel

was introduced and is actually widely used for implant fabrication. This alloy

has a very good resistance to chloride solutions and poor sensitoion. Since the 1960s, titanium has become a

popular metallic biomaterial because of its properties for many biomechanical

applications including dentistry. Although there is an increasing trend for

metal-free restorations in the dental profession,

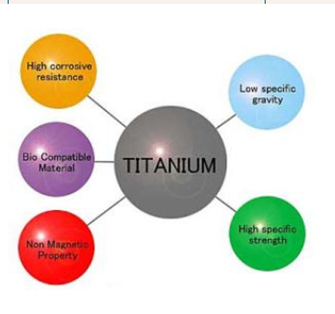

Material properties of

Titanium

Titanium is often used either as the pure metal, or in an

alloyed form in aerospace applications, and in medical and dental work. It is

commonly alloyed with other metals such as Vanadium and Aluminum . It forms

then light-weight but at the same time strong alloys for the fabrication of

oral implants or the frameworks for FDPs.

According to the American Society of Testing Materials, cpTi is available in four different grades that is based on the incorporation of small amounts of oxygen, nitrogen, hydrogen, iron and carbon during purification procedures, where each grade has different physical and mechanical properties. Grades I and II are the most commonly used cpTi types for the production of metal-ceramic FDPs. In oral implants and implant-supported FDPs, cpTi and its alloys exhibit remarkable advantages due to their excellent biocompatibility, corrosion resistance, high strength, and low modulus of elasticity .Yet, the recent trends in making dental biomaterials more biomimetic from both biomechanical and biological perspectives, also applied for cpTi. Principally, the stress transfer between a metal framework and the dental tissues or bone is not homogeneous since stiffness of the metal framework or implants and such tissues are different. This phenomenon is described as “stress shielding”. In order to avoid devitalization of the tooth and atrophy in the bone under chewing function , high Young’s modulus of cpTi compared to those of the tooth and the bone structures, is not desirable. Young’s moduli of the most widely used SUS316L stainless steel and Co-Cr for orthopaedic implant devices, are approximately 180 GPa and 210 GPa, respectively whereas Young’s moduli of cpTi and its alloys are generally lower than those of stainless steels and Co-Cr alloys.

Titanium and biocompatibility

Because the focus of

biomaterials has shifted more towards, tissue engineering, complex medical

application and biotechnology, it has become necessary to better define and

evaluate the specific interaction between biomaterials and tissues .Biocompatibility

refer to the ability of the biomaterial to perform the desire function with the

respect to medical therapy

Beside

the artificial bones, joints replacement and the dental implants, titanium

based alloy also used in the cardiovascular implants

Titanium medical specification

Bone and Joint Replacement

About one million patients worldwide are

treated annually for total replacement of arthritic hips and knee joints. The

prostheses come in many shapes and sizes. Hip joints normally have a metallic

femoral stem and head which locates into an ultrahigh molecular weight low

friction polyethylene socket, both secured in position with polymethyl

methacrylate bone cement. Some designs, including cementless joints, use

roughened bioactive surfaces (including hydroxyapatite) to stimulate

osseointegration, limit resorption and thus increase the implant lifetime for

younger recipients. Internal and external bone-fracture fixation provides a

further major application for titanium as spinal

fusion devices, pins, bone-plates, screws, intramedullary nails, and external

fixators

Maxillofacial and

Craniofacial Treatments

Surgery to repair facial damage using

the patients own tissue cannot always obtain the desired results. Artificial

parts may be required to restore the ability to speak or eat as well as for

cosmetic appearance, to replace facial features lost through damage or disease titanium

implants meeting all the requirements of biocompatibility and strength have

made possible unprecedented advances in surgery, for the successful treatment

of patients with large defects and hitherto highly problematic conditions.

Titanium is regularly used for pacemaker

cases and defibrillators, as the carrier structure for replacement heart

valves, and for intra-vascular stents.

External Prostheses

Titanium is suitable for both temporary

and long term external fixations and devices as well as for orthotic callipers

and artificial limbs, both of which use titanium extensively for its light

weight, toughness and corrosion resistance.

Surgical Instruments

A wide range of

surgical instruments are made in titanium. The metal’s lightness is a positive

aid to reducing any fatigue of the surgeon. Instruments are frequently anodised

to provide a non reflecting surface, essential in microsurgical operations, for

example in eye surgery. Titanium instruments withstand repeat sterilisation

without compromise to edge or surface quality, corrosion resistance or

strength. Titanium is non magnetic, and there is therefore no threat of damage

to small and sensitive implanted electronic devices.

Titanium for dental implant

In this era the

chemical pure titanium is the dominant and very useful material for the dental

implant there has been major change occur in the change in restorative dental

practice worldwide has been possible through the use of titanium implants. A

titanium ‘root’ is introduced into the jaw bone with time subsequently allowed

for osseointegration. The superstructure of the tooth is then built onto the

implant to give an effective replacement.

Surface modification of dental implant

There has been huge research

has been proven on surface modification of micro and nanorough for titanium and

titanium implants. If the relatively impact structure replaced with the

nanostructure surface and coating numerous possibilities of the structure lead

to the significant improvement in the field industry tissue.

The mechanical methods

most widely used in obtaining rough and smooth ti and ti based alloy surface

and its fabrication nanophase surface layer and subtraction and attrition

process.

Conclusion

As the titanium and its

alloy are considered as most promising material among the wide range of the

application. Due to his unique combination of the high strength to weight ratio

, melting temperature and the corrosion resistance . The principal alloys in

practical use are commercially pure titanium. The mechanical properties of the

latter are better, but the slight concern over the biological effects of the

very minor amounts of aluminium and vanadium that they release means that cpTi

is the more widely used of the two. Despite these concerns, there is a large

amount of experimental evidence to show that both alloys have good bioactivity

and the ability to osseointegrate. Additionally, there are few, if any,

accounts of adverse effects arising from release of aluminium and/or vanadium

from dental implants, probably because amounts released are so low. The use of

the titanium is in the very wide area such as it is use in the mediacl field in

bone and joint replacement,

cardiovascular process, surgical instrument. And the main use of the

titanium is in the dental application and it is useful in many fields. For this

reason, the two well-established alloys of titanium continue to be used for the

overwhelming majority of implants used in dentistry, and this use seems likely

to continue for the foreseeable future.

Comments

Post a Comment